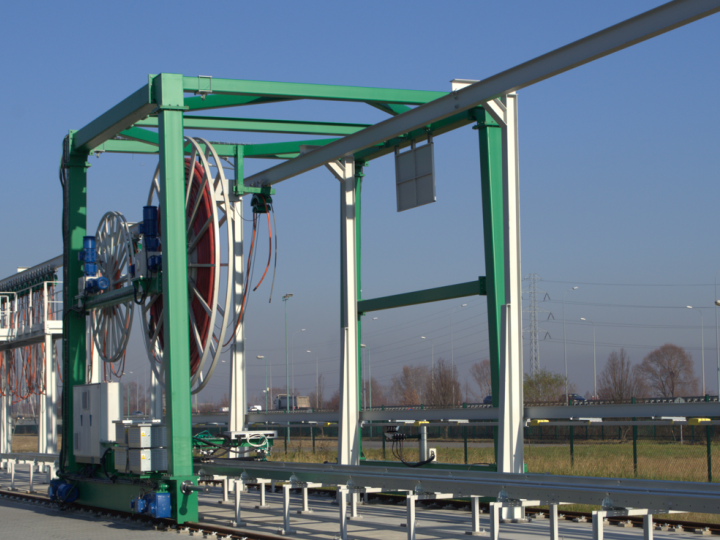

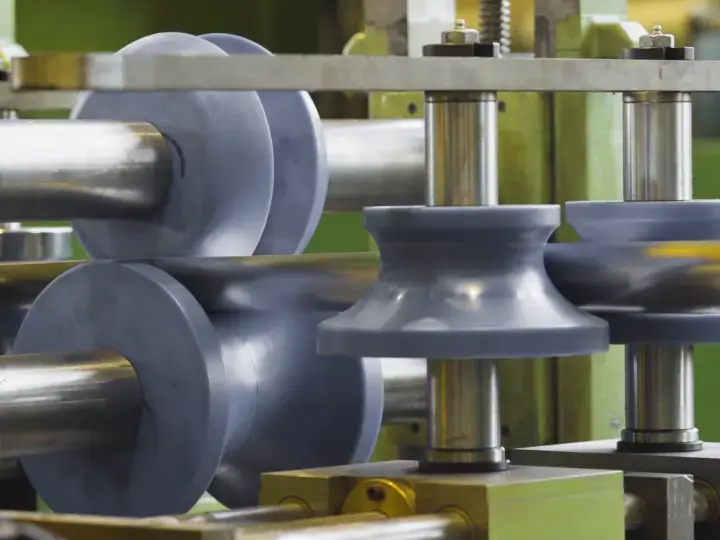

Expansion of the Bydgoszcz plant. The project includes the construction of a 53 metre high CCV tower dedicated to the production of long sections of high and extra-high voltage cables. This phase is scheduled for completion by the end of 2025, and the TFKable Group is already preparing the second phase of expansion for 2026-2028, including further investments in machinery and equipment.

The investments in Bydgoszcz focus not only on the expansion of the plant, but also on the implementation of modern technologies and innovative production solutions. Expansion of the Research and Technology Centre with a new tower with a flyover, designed to facilitate the production of long sections of high and extra-high cables.